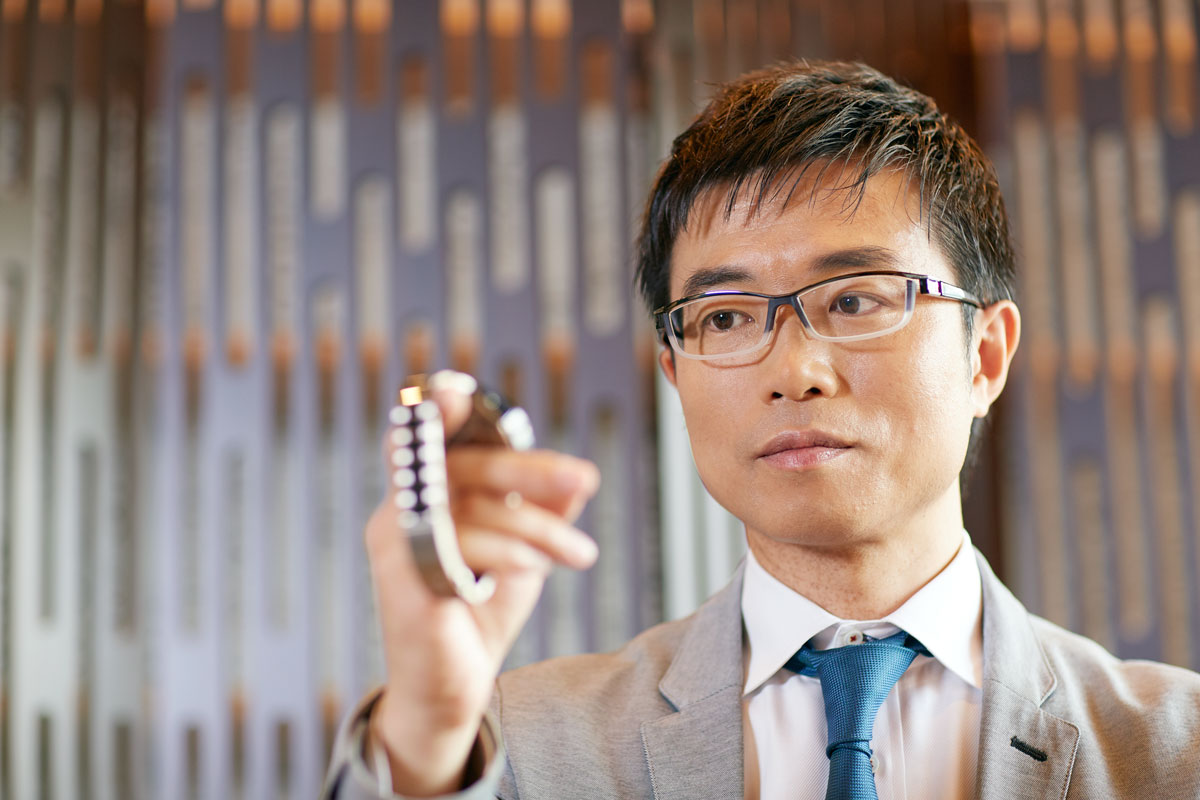

The Legacy of the Grand Seiko Sport Collection Interview with Shinichiro Kubo

The watch designer Shinichiro Kubo has designed many “firsts” in the Sport Collection, such as Grand Seiko’s first model with a Spring Drive, the first diver’s model, and the first ceramic model, as well as the mechanical GMT model released in 2018 to celebrate the 20th anniversary of the Caliber 9S. In this interview, he discusses the core philosophy and future outlook of the Sport Collection.

The Design of the Grand Seiko Sport Collection

Grand Seiko was born in 1960, based on Seiko’s determination to create the best watch in the industry. Since then, as a result of its efforts to stand at both the origin and the pinnacle of watchmaking at the same time, Grand Seiko has released a large number of models that boast the industry’s highest quality and that pursue the very essence of watches at the highest level. Based on our concept of manufacturing the best watches for everyday use, the core of Grand Seiko consists of the Heritage Collection, which features a meticulous basic design that will be loved by users over many years. There is also the Sport Collection that offers models for use in more active environments, such as the domain of sports, which is new to us, inheriting the brand’s unique design approaches such as Grand Seiko Style, established by the classic 44GS released in 1967.

The Sport Collection offers Grand Seiko’s first chronograph equipped with Spring Drive Caliber 9R86 released in 2007 (SBGC001). The collection also boasts professional diver’s watches that have all the aesthetics of Grand Seiko while remaining true to the basic functionality of diver’s watches, as well as beautiful ceramic watches with a hybrid case made from zirconia ceramic and high-intensity titanium. The Sport Collection is designed to powerfully express the essential elements of watches pursued by Grand Seiko, which can be summarized in three words: precision, legibility, and beauty.

Watch Designer

Shinichiro Kubo

Shinichiro Kubo joined Seiko (now Seiko Holdings) in April 1999. He was transferred to Seiko Watch Corporation in 2001 to design international as well as domestic watch models including the Seiko iZUL, a sports watch equipped with a Spring Drive chronograph. Starting in 2003, he has worked on designs for Grand Seiko watches, mainly for the Sport Collection, and he has designed a wide variety of watches including Grand Seiko’s first model with a rotating bezel (2005) and Grand Seiko’s first chronograph (2007) in addition to other ceramic models, diver’s watches, and GMT watches.

Grand Seiko’s first spring-driven chronograph with the highest precision in the industry

.jpg)

Grand Seiko’s first chronograph equipped with Spring Drive Caliber 9R86 was released in 2007 as the SBGC001. First of all, what are the functional features of the Spring Drive?

The Spring Drive is Seiko’s proprietary driving mechanism that uses the torque generated when the mechanical watch spring unwinds as its energy source, and a quartz crystal oscillator—the quartz watch speed control mechanism—to maintain precision. Thus, the Spring Drive combines the benefits of a mechanical watch and a quartz watch—which are the power source and the control system, respectively (both are major factors in keeping a watch running). This dual mechanism enables the watch to deliver a high level of accuracy, with an average deviation of just ±15 seconds a month despite the watch being spring-driven.

What are the design features of the SBGC001?

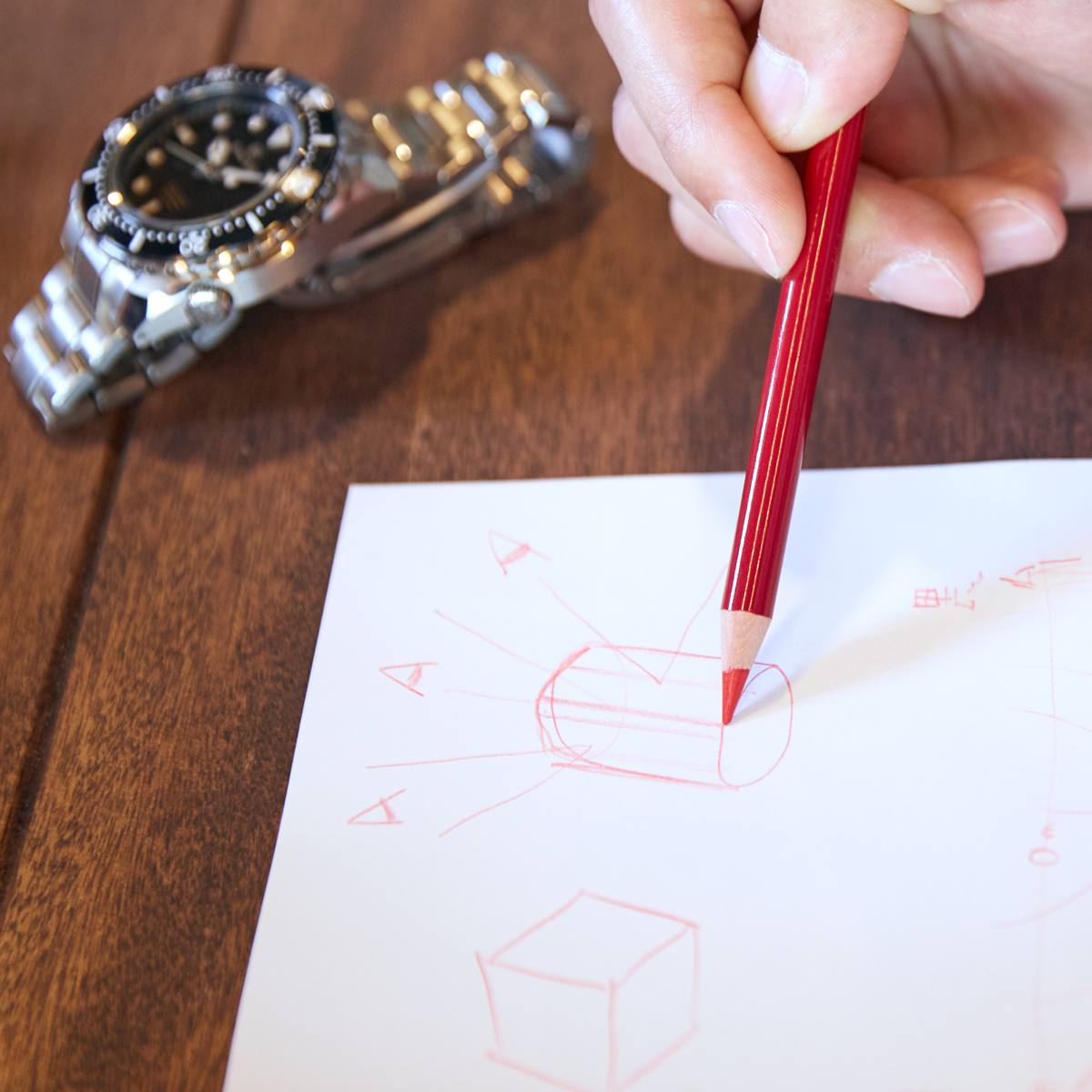

The greatest feature is that the watch can maintain its high precision thanks to the Spring Drive while ensuring an accurate stopwatch function. Before talking about the exterior of the watch, I would like to explain its mechanism.

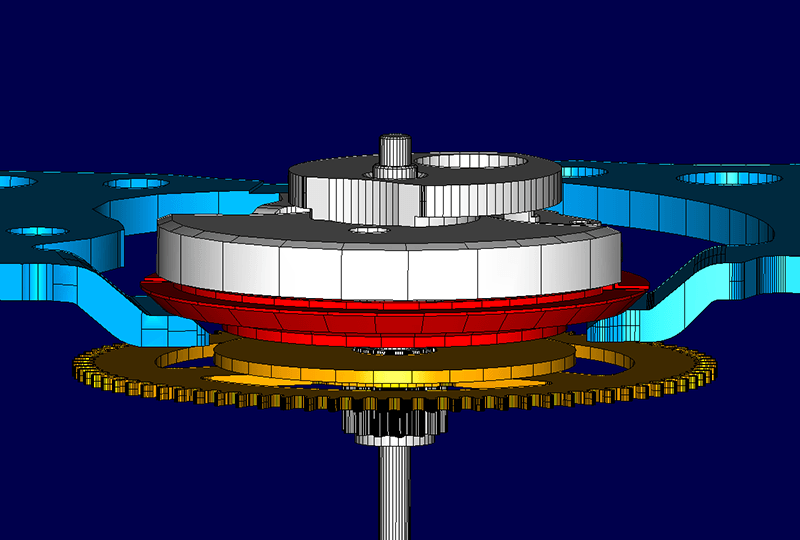

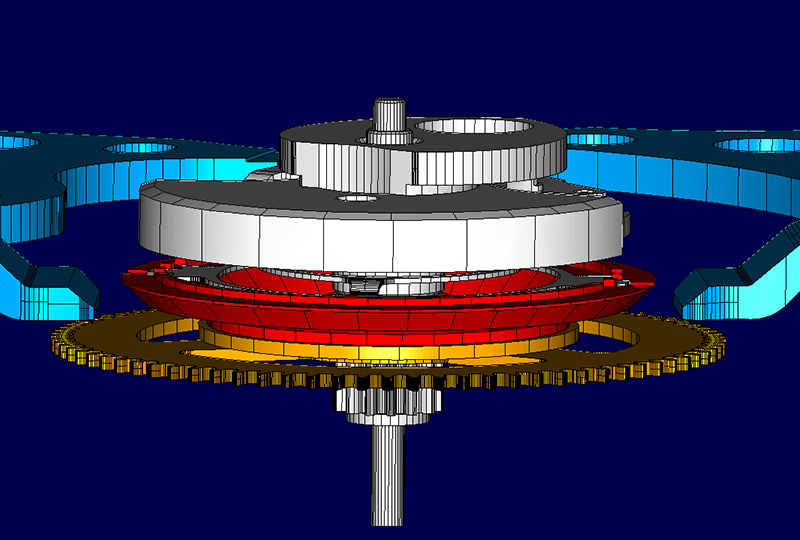

In general, a stopwatch is a function you use on an as-needed basis, and it is in off-mode most of the time. Our Spring Drive movement employs a “vertical clutch,” a system in which the clutch utilizes the contact of surfaces between upper and lower gears, rather than the conventional engagement between gears, this in turn eliminates the jumping of the second hand inherent in traditional clutches. This system offers ultimate stability, thus ensuring the reliable operation of the Spring Drive with unparalleled precision. There is also the abrasion-free benefit because, when the chronograph is turned on, the gears move as a unit, and their contact surfaces do not rub against each other.

The push button for the stopwatch is particularly eye-catching.

.jpg)

(The photo above shows the SBGC201, a model equivalent to the SBGC001 with the position of the Grand Seiko logo changed on the dial.)

Yes, I know that this push button stands out, although the watch itself has a standard design. But this size is necessary in order to make the chronograph work for this model. In 1964, Seiko served as an official timekeeper at an international sport competition to help support its success, which made the company’s name widely known to the world. In particular, the accuracy of Seiko’s 1/100-second mechanical stopwatch was well received among judges, and many users appreciated the perfect touch of the push button.

The SBGC001 has been developed based on this stopwatch, which was a product created as a result of the full commitment of Seiko’s technical team at that time. The READY/START mode of the watch ensures that stopwatch operation will be error free and accurately start by half-pressing the push button. In order to produce a perfect click that is neither too heavy nor too light, all component sizes—including the diameter of the push button—have been fine tuned. In addition, a screw-lock mechanism is fitted to prevent any accidental operation of the button. As explained, we had to keep the size of the push button somewhat large due to various functional requirements.

Are there any other design elements you have emphasized?

In order to achieve greater visibility, we had to carefully decide upon the distance between the hand and the scale of the stopwatch dial. Regardless of its accuracy in timekeeping, if the tip of the second hand is too far from the scale, the time on the stopwatch is hard to read. The scale in 1-second increments is divided into 60, so you can read it fairly intuitively, but reading a smaller scale in 1/5-second increments is a bit hard, and it may also tire your eyes. As a result of numerous tests, we discovered that the optimum distance between the tip of the second hand and the scale for maximizing legibility is 0.06 millimeter. To realize this, the stopwatch hand is deliberately designed to hover over the scale, which is positioned on the bezel slope of the dial ring.

At first glance, the stopwatch hand may seem to point to the scale in the same way as in ordinay watches. In fact, to achieve this “ordinariness,” a very inventive approach is used in a place you cannot see. The simplest way to assemble a watch is to build the housing, insert the movement, and then close the caseback. However, for this chronograph, each component is assembled one by one from both the top and the bottom of the watch: The movement and then the dial are fixed onto the ring, the dial ring is fixed onto this assembly, and finally the hands are installed. The reason we have adopted this complicated structure is because doing so is necessary in order to firmly position the stopwatch hand on the dial ring and eliminate any misalignment between this hand and the scale. This structure is one of the key features of this model.

The first diver’s watch from Grand Seiko

Showcasing exquisite form while remaining true to the basic functionality of a diver’s watch

.jpg)

In 2008, Seiko released the first diver’s watch from Grand Seiko, equipped with a Spring Drive.

To tell you the truth, this was the first diver’s watch model that I designed. First and foremost, I thought I could not begin to design the watch without scuba diving myself. So immediately after I was officially appointed designer, I called a friend who lived in Okinawa and said, “I’m heading your way now, so see you soon,” and flew to Okinawa. Then I joined a diving course for beginners and dove into the sea for the first time in my life, wearing Seiko’s latest diver’s watches on both wrists. While scuba diving, I observed and considered a lot of things regarding the important elements of a diver’s watch, such as the readability and visibility of those watches at depths of 10 and 30 meters. We also visited the Japan Agency for Marine-Earth Science and Technology (JAMSTEC) with Seiko’s engineers, who are the pioneers in the development of Japanese diver’s watches, to discuss design with professional divers.

How did such experiences help you when developing the design concept?

Ever since releasing the first diver’s watch made in Japan in 1965, Seiko has introduced new models equipped with unique, innovative technologies, which have won enormous confidence from professional divers, adventurers, and customers around the world. Therefore, as long as I was designing a diver’s watch under the Grand Seiko brand, I was determined to fully incorporate all the basic features divers expect into our model.

Based on the thoughts above and the knowledge gained from interviews with experts as well as my own diving experience, we identified the major requirements of a diver’s watch so as to define the important points we should keep in mind when developing a design. First, the time must be legible accurately under harsh environments. The keys to achieving this requirement are the minute hand and the numbers on the bezel. Next, the elapsed time from the start of a dive must be notified so that the diver can check the remaining amount of air.

In addition, we also had to consider the fact that if you dive deep, your mind can become confused. According to an expert at JAMSTEC, when your thoughts become unclear due to reasons such as helium intoxication, the only shapes you are able to distinguish are basic geometries such as circles, triangles, or rectangles, rather than complicated geometries such as numbers and arrows. As a diver’s watch may determine life or death for the user, the orientation of the watch must be easily recognizable before the numbers can be read. Therefore, I was strongly committed to incorporating these basic geometries, which are one of the fundamental features of a diver’s watch, into this model. The diver’s watch is the only Grand Seiko model that uses these geometries for its indexes.

What are the design features of this watch?

.jpg)

At first glance, the indexes seem flat and totally integrated into the dial, but if you look closely, you will see that they are sculpted three-dimensionally, as if they were floating on the dial. Even for a diver’s watch, which is a synonym for function over form, I wanted to incorporate a premium texture, as we were to release it under the Grand Seiko brand. To this end, I decided to use beautiful, thick, solid indexes. Therefore, we used a technique called “swaging” to create these indexes, which are chamfered and fixed one by one on the dial. After numerous trials and errors, we succeeded in finishing the product based on the unparalleled skills of our artisans and thorough quality control. At first, however, the chances looked slim-to-none that we would be able to complete such a design.

This was because it was unthinkable to install three-dimensional parts on the dial of a diver’s watch because it must project the confidence that it can withstand even the harshest conditions. For example, if a three-dimensional part were to come off as a result of an accident and become stuck between the hands of the watch, this might cause a life-and-death situation for the diver. Also, given that we were going to sell this diver’s watch under the Grand Seiko brand, the three-dimensional parts had to be attached using a method that is far more reliable than one used for ordinary products. No matter how many times I discussed methods of achieving this with watch artisans, they kept replying, “No, we can’t do this.” However, we succeeded in inventing and adopting a swaging method in which the thick and firm legs of the index parts could be sturdily and reliably embedded on the dial, thus developing Grand Seiko’s first diver’s watch.

Professional diver’s watch with luxurious brilliance based in Grand Seiko’s aesthetics

In 2017, we released the first professional diver’s watch from Grand Seiko designed for saturation diving. This watch has a much thicker and heavier feel compared with previous diver’s watches for air diving.

The diver’s watch released in 2008, which we discussed earlier, is water resistant up to 200 meters for air diving. On the other hand, this model, equipped with a world-class, high-oscillation 10-beat mechanical movement, offers extremely high air-tightness and water-tightness up to 600 meters for saturation diving, which is considered to be the most extreme environment for human activity. In addition, the crown is positioned at 4 o’clock (positioned at 3 o’clock for normal watches) to prevent the watch from getting caught in a line, satisfying the more particular needs of professional divers.

What are the important design features of this watch?

.jpg)

One of the most interesting facts that I found out scuba diving myself is that, as you go deeper and deeper into the water, colors such as red, orange, and yellow disappear, and you finally enter a monochrome world. The colors look so strange in that world—black looks darker, and white looks more vivid and whiter. Based on this phenomenon, we developed a design for professionals, whereby the details of the watch that are indispensable to divers, such as the dial, indexes, and minute hand, look more highlighted as you dive deeper into the sea, and the case reflects light more strongly. Overall, the design was created with more focus on the plane than on the lines. This new model is based on the basic philosophy of Grand Seiko Style, beautifully combining the rediant brilliance and exquisite form unique to Grand Seiko with the excellent legibility and antimagnetic performance of a professional diver’s watch.

I also heard that the watch is designed for long-term use and maintenance.

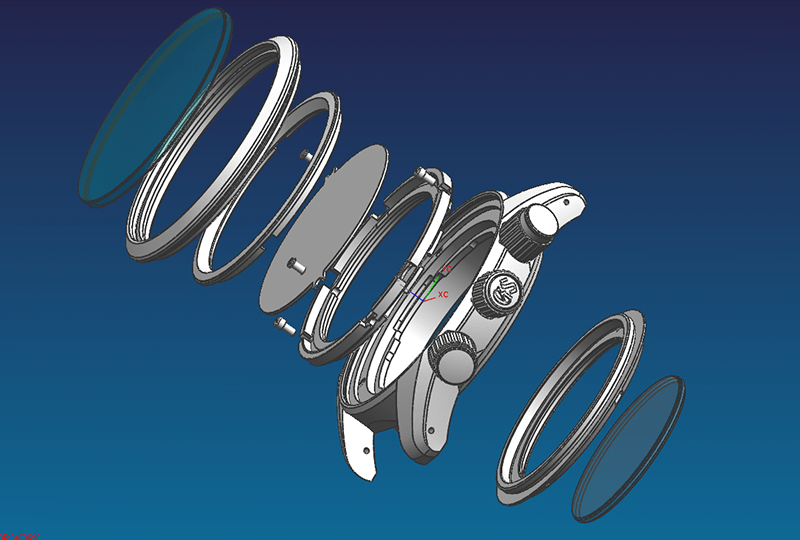

.jpg)

Yes, all parts including the bezel and the crown can be disassembled and reassembled. The case and bracelet, which are prone to scratching, can be replaced individually, and through repolishing, their graceful and beautiful brilliance can be restored. As all Grand Seiko watches—not only this model—are designed keeping in mind how to preserve the high quality of the watches over a long period of time, with maintenance, the movement and housing can be used almost indefinitly.

Hybrid case made from zirconia ceramic and high-intensity titanium

Following the Grand Seiko’s first black ceramic limited model introduced in 2016, a regular model was released in 2017. What are the benefits of the ceramic material?

As mentioned earlier, Grand Seiko’s watches can be disassembled for repolishing of exterior parts that have become scratched. But I thought, maybe we should manufacture the watch using scratch-resistant materials in the first place, so we started studying how to use ultra-hard ceramics.

For the ceramic model, we selected a beautiful material called “zirconia ceramic,” which has the highest strength and toughness among all ceramic materials, and is easy to process for high-quality surface polishing.

What was the reason behind you selecting a hybrid structure of zirconia ceramic and high-intensity titanium?

High-intensiy titanium is a high-functionality titanium that has a Vickers hardness about 1.5-times that of the pure titanium used in other Seiko products, with reinforced tensile strength. By using this titanium in the inner case of the watch, we have developed a structure that ensures excellent water-resistance performance and firmly protects the movement.

The movement is protected with a high-intensity titanium case, and zirconia ceramic is employed as the material for the bezel and lugs, which are prone to scratching through wearing the watch. This makes it a timepiece featuring a robust housing as well as having a light and comfortable fit.

For this model, we focused on using innovative materials, while ensuring visibility by the use of a long hand that reaches the edge of the dial. Thus, this model embodies the essence of watches pursued by Grand Seiko: precision, legibility, and beauty.

What is your outlook in terms of the future design and evolution of the Sport Collection?

Grand Seiko has strived to create watches with the highest precision and most beautiful brilliance in the industry for more than a quarter of a century. In an effort to expand its portfolio, the brand gave birth to the Sport Collection, together with the Elegance Collection. I will continue to abide by the core philosophy of Grand Seiko while exploring powerful forms in terms of design and seeking to strike a good balance by achieving excellent functional performance such as the robustness and water resistance required in the active, special world of sports.