From sports timing to a high precision chronograph

This is the story of Grand Seiko. It is a story of vision, determination, commitment, innovation and, most of all, of the quiet, calm and utterly single-minded determination of two generations of watchmakers to create watches that are absolutely as good as they can possibly be. The first Grand Seiko appeared in 1960 but the story started long before and continues to unfold and gather pace today. Who knows? Perhaps the best is yet to come.

Grand Seiko's next challenge: Developing the chronograph

Central to the DNA of Grand Seiko is high precision, so it was natural for the Grand Seiko team in the early 2000s to want to create a chronograph as its first real “complication.” The team had all the experience required to achieve this thanks to the company’s long history at the forefront of two key areas of horology, sports timing and the manufacture of Seiko mechanical chronographs.

Seiko had been the official timekeeper at a total of six Olympic Games, starting with Tokyo 1964 and Sapporo 1972 through to Barcelona 1992, Lillehammer 1994, Nagano 1998 and Salt Lake City 2002. This was a responsibility that required a very high level of technological proficiency and a complete understanding of the rigors of sports timing of every kind and, of course, the elapsed time stopwatch was, from the very start, a central part of the timing service. At the Tokyo Olympic Games, Seiko’s hand held mechanical stopwatches had won high praise for their precision and the logical next step was to see if the same level of accuracy could be achieved in a wristwatch. In 1969, a year in which Seiko made several world first breakthroughs, the world's first automatic day-date chronograph, the Seiko 5 Sports Speed-Timer, was created. Caliber 6139 brought the precision of world class sports timing to the wrist with the use of a vertical clutch to transmit power to the chronograph mechanism. This system remains the gold standard today and is used in all the best chronographs because it prevents the seconds hand from jumping when the stopwatch is started.

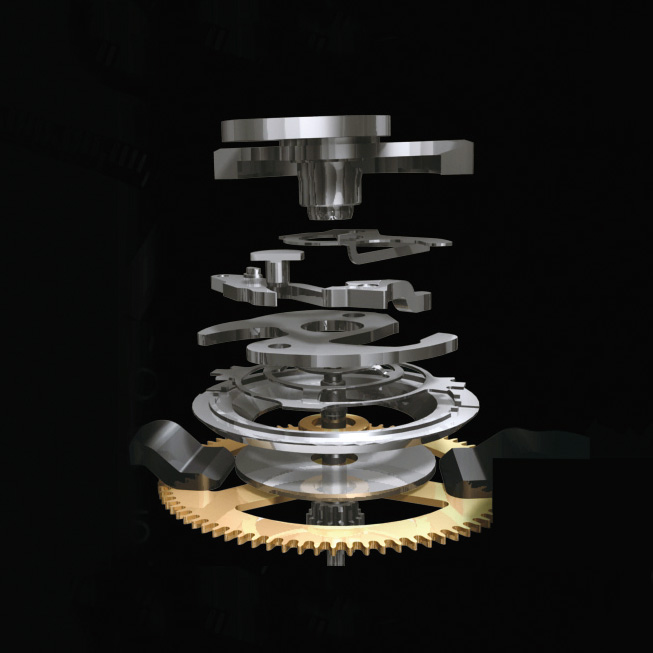

The energy that powers the time of day movement also drives the chronograph. This power is transmitted to the chronograph mechanism when the start button is pressed. The company invented its vertical clutch system using a disc spring in Caliber 6139 in 1969. This prevents the seconds hand from jumping when the power is transmitted, and increases the accuracy of elapsed time measurement. A new version of this very successful mechanism was used in the Spring Drive Chronograph.

With such a history, it was natural for the Grand Seiko team to want to create a chronograph movement. However, the Grand Seiko standards of precision, operability, and legibility were high and no existing technology would allow the creation of a chronograph that would match them. The idea was shelved for several years until, in 1999, Spring Drive was created, a development that opened up new opportunities for a luxury chronograph.

Achieving the durability and functionality that a Grand Seiko chronograph demanded

Immediately after the launch of the first Spring Drive movement, development of the first Grand Seiko chronograph began. The aim was simple, to make world's most accurate spring driven chronograph. In fact, the original Spring Drive three hand movement had already been conceived as a platform on which other calibers could be built. For example, by placing the power reserve indicator at the 7 to 8 o'clock position, the layout allowed for the future addition of other subdials without compromising the legibility. In other respects, the design was unique, most notably in the form of the large, screw-down push buttons which helped the chronograph operation live up to the extraordinary precision of the caliber. Released in 2007, the first Grand Seiko chronograph more than achieved its aim. Powered by a mainspring, it achieved an accuracy of one second per day, a power reserve of 72 hours, even when the chronograph was in operation and, thanks to the glide motion of the hands, measuring elapsed time to the exact moment not to the nearest “tick”. The spring-driven chronograph had indeed been re-defined.

Subsequent focus switched on to the aesthetics and exterior qualities of the chronograph. Until 2016, all Grand Seiko chronographs had been in steel but the team decided that such a revolutionary caliber deserved a more innovative presentation. They turned to ceramic. This material was selected because it would make the watch lighter and perhaps more comfortable to wear. Furthermore, the scratch resistance of ceramic had the advantage of preserving the perfect, distortion-free mirror finish and sharp ridges of the design.

Durability being an essential requirement in any Grand Seiko watch, the risk of ceramic being damaged by shock had to be eliminated, so the design team created an inner case made of high-intensity titanium, with the ceramic parts on the exterior. To preserve the smooth and slim profile of the case, the bezel angle was curved and the lugs were given more volume to lower the visual center of gravity and to let the watch sit snugly on the wrist.

A concept model, which combined Zaratsu polished steel and a hard rubber inner case, was made in 2013. It proved that a composite case structure could work and led the way to the use of ceramics and titanium.